On this page, I will explain the strength of ceramics, which is one of the most important characteristics. The material strength is an essential parameter when you will develop your new products. Also, It is necessary to collect a lot of highly reliable strength data to ensure the quality of products.

Strength

In general, the strength is ambiguous and requires a modifier to express the meaning. There are a lot of strength ,for example, yield srtength, tensile strength, compressive strength, flexural strength, ultimate strength, fracture strength, theoretical strength and so on.

There are various strength characteristics, but you should understand clearly. If you do it, you can use the various strength as a guideline when you select new materials.

Theoretical strength

The theoretical strength is defined as the tensile strength which is required to break the bonds between atoms. The theoretical strength using tensile stress can be estimated by the following formula. $$σ=(\frac{Eγ}{a_0})^{\frac{1}{2}}$$

Here, σ is the theoretical strength, E is the elastic modulus, a0 is the interatomic distance, and γ is the surface energy.

In general, the theoretical strength of ceramic materials is from 1/10 to 1/5 of the elastic modulus. For example, the elastic modulus of Al2O3 is 380 GPa, so the theoretical strength is expected to be around 38 to 76 GPa. However, theoretical strength of ceramics is not usually achieved. This is why there are small defects in the materials and the stress concentrates on them.

Table 1 shows the theoretical strengths and tensile strengths of fibers and polycrystals about Al2O3 and SiC. The fracture strength of polycrystals in Al2O3 and SiC is only 1/100 of the theoretical strength.

Table1 theoretical strength and actual strength

| Materials | Elastic modulus [GPa] | Theoretical strength [GPa] | Fibre strength [GPa] | Polycrystalline strength [GPa] |

| Al2O3 | 380 | 38 | 16 | 0.4 |

| SiC | 440 | 44 | 21 | 0.7 |

Strength data of ceramic materials

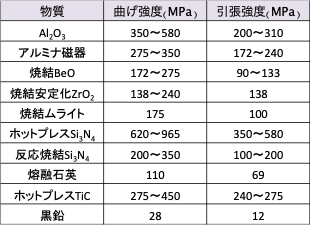

Table 2 shows strength data of various ceramic materials. You can use this table to get rough strength datas of ceramics.

Also, high temperature strength is more important than room temperature strength in many products. With the exception of graphite, almost all ceramic materials weaken strength with increasing temperature.

In general, the strength decreases with higher temperature and is proportional to the decrease in elastic modulus. However, it is limited in moderate temperature behavior (〜 1000 ℃). At high temperatures, the strength decreases rapidly with inelastic effects. In most ceramics, there are a lot of the chemical secondary structure in the grain boundaries, which soften and reduce the bearing capacity of ceramic at high temperatures.

Table2 the strength of various ceramics, rt

| Materials | flexural strength(MPa) | tensile strength(MPa) |

| Al2O3 | 350〜580 | 200〜310 |

| Al2O3 porcelain | 275〜350 | 172〜240 |

| Sintering BeO | 172〜275 | 90〜133 |

| Sintering ZrO2 | 138〜240 | 138 |

| Sintering mullite | 175 | 100 |

| Hot press Si3N4 | 620〜965 | 350〜580 |

| Reactive sintering Si3N4 | 200〜350 | 100〜200 |

| Fused quartz | 110 | 69 |

| Hot press TiC | 275〜450 | 240〜275 |

| Graphite | 28 | 12 |

コメント